WHAT WE DO

products groups

- FIBER-OPTIC-CABLE

- PRE-TERMINATED-FIBER-OPTIC-CABLE

- OUTDOOR-FIBER-OPTIC-SPLITTER-CLOSURE

- FIBER-OPTICAL-SPLICE-CLOSURE

- FIBER OPTIC FAST CONNECTORS AND ADAPTER

- FIBER-SPLITTERS-ADAPTERS

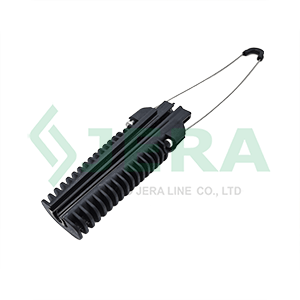

- FIBER-POTIC-CABLE-CLAMPS

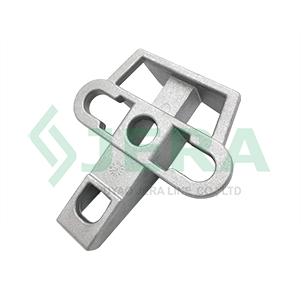

- FIBER-OPTIC-CABLE-POLE-BRACKETS,HOOKS

- FIBER-OPTIC-CABLE-SLACK-STORAGE

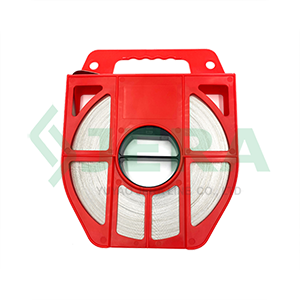

- STAINLESS-STEEL-BANDINGS

- DEAD-END-GRIP

- FIBER CABLE TOOLS

FIBER-OPTIC-CABLE

PRE-TERMINATED-FIBER-OPTIC-CABLE

OUTDOOR-FIBER-OPTIC-SPLITTER-CLOSURE

FIBER-OPTICAL-SPLICE-CLOSURE

FIBER OPTIC FAST CONNECTORS AND ADAPTER

FIBER-SPLITTERS-ADAPTERS

FIBER-POTIC-CABLE-CLAMPS

FIBER-OPTIC-CABLE-POLE-BRACKETS,HOOKS

FIBER-OPTIC-CABLE-SLACK-STORAGE

STAINLESS-STEEL-BANDINGS

DEAD-END-GRIP

FIBER CABLE TOOLS

WE MANUFACTURER & RND

GUARANTEE RESPONSIBILITY

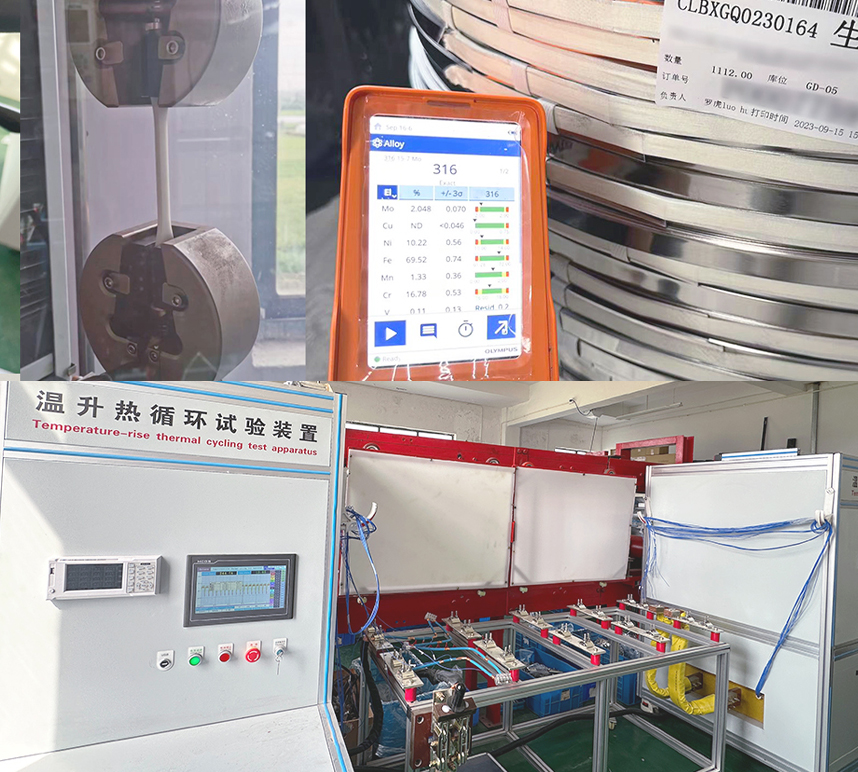

OUR FACTORY LABORATORY

WHY COMPETITIVE PRICE

HOW WE SAVE LOGISTICS COSTS

GLOBAL EXPERIENCE

why choose us

Since our establishment in 2012, JERA LINE has been a dedicated Chinese factory specializing in the production of cable infrastructure products. Our unwavering commitment lies in delivering high – quality products and services to customers around the globe.

Production Scale and Facilities

Situated in Yuyao, Ningbo, our factory currently spans an area of 3,000 square meters. With continuous expansion plans in place, we are constantly growing. Equipped with dozens of advanced devices, our factory ensures efficient production processes. Our production portfolio encompasses a wide range of optical cable components for telecommunication network construction, including but not limited to optical cables, fixtures, and enclosures for both outdoor and indoor FTTX deployments, effectively meeting the diverse needs of different customers for cable infrastructure products.

Fiber Range Products

Our fiber range products are designed to provide comprehensive solutions for deploying optical cables through FTTX and FTTH technologies in outdoor, indoor, and underground applications, contributing significantly to the construction of efficient and stable communication networks.

- Optical Cable Series

- Outdoor Optical Cables: Engineered to withstand harsh environmental conditions, our outdoor optical cables are ideal for long – distance transmission in open – air environments. They feature robust sheathing materials that offer excellent protection against moisture, UV radiation, and mechanical damage. These cables are available in various fiber counts and types, catering to different bandwidth requirements, whether for large – scale backbone networks or neighborhood – wide connectivity.

- Indoor Optical Cables: Designed for indoor installations within buildings, our indoor optical cables prioritize flexibility and fire resistance. Their lightweight and flexible construction make them easy to route through tight spaces, such as ceilings, walls, and data centers. The flame – retardant jackets ensure safety in enclosed environments, while maintaining high – performance signal transmission for seamless communication within the building’s network infrastructure.

- Fixtures and Accessories

- Optical Cable Clamps: Our optical cable clamps are essential for securely fastening optical cables during installation. They are crafted from high – quality materials, providing reliable grip without causing damage to the cable sheath. Available in different sizes and designs, these clamps can be easily adjusted to accommodate various cable diameters, ensuring a stable and long – lasting connection.

- Optical Distribution Frames (ODFs): Our ODFs are highly efficient and space – saving solutions for organizing and managing optical fiber connections. With a modular design, they allow for easy installation, maintenance, and expansion of optical fiber networks. The ODFs feature a well – structured interior layout, providing ample space for cable routing, splicing, and termination, while protecting the optical fibers from external interference and physical damage.

- Connectors and Adapters: We offer a comprehensive range of high – precision optical fiber connectors and adapters. These products ensure low – loss, high – speed optical signal transmission with excellent repeatability and durability. Compatible with various types of optical fibers, our connectors and adapters are easy to install and provide a stable connection, facilitating seamless integration of different optical fiber components within the network.

Quality Control

In our daily operations, we strictly adhere to the ISO 9001 standard. For technical operations, we apply testing standards from different international regional standard test scopes, such as EN – 50483:4, NF C 33 020, NF C 33 041, IEC 61238 – 1, IEC 60099 – 4:2014, and others. Our on – site laboratory enables us to conduct quality inspections. We also collaborate with numerous third – party institutions, especially those accredited by ISO/IEC 17025:2018, which are qualified to perform relevant tests and issue test reports and certificates.

Product testing is regarded as a crucial part of our business. We ensure that our products meet international standards for power cable products. We cooperate with well – known local quality inspection agencies like SGS and Bureau Veritas. When conducting business in different countries and regions around the world, we take into full account the requirements and standards of each market, making our products more suitable for specific market needs. We can also customize products according to customers’ standard requirements.

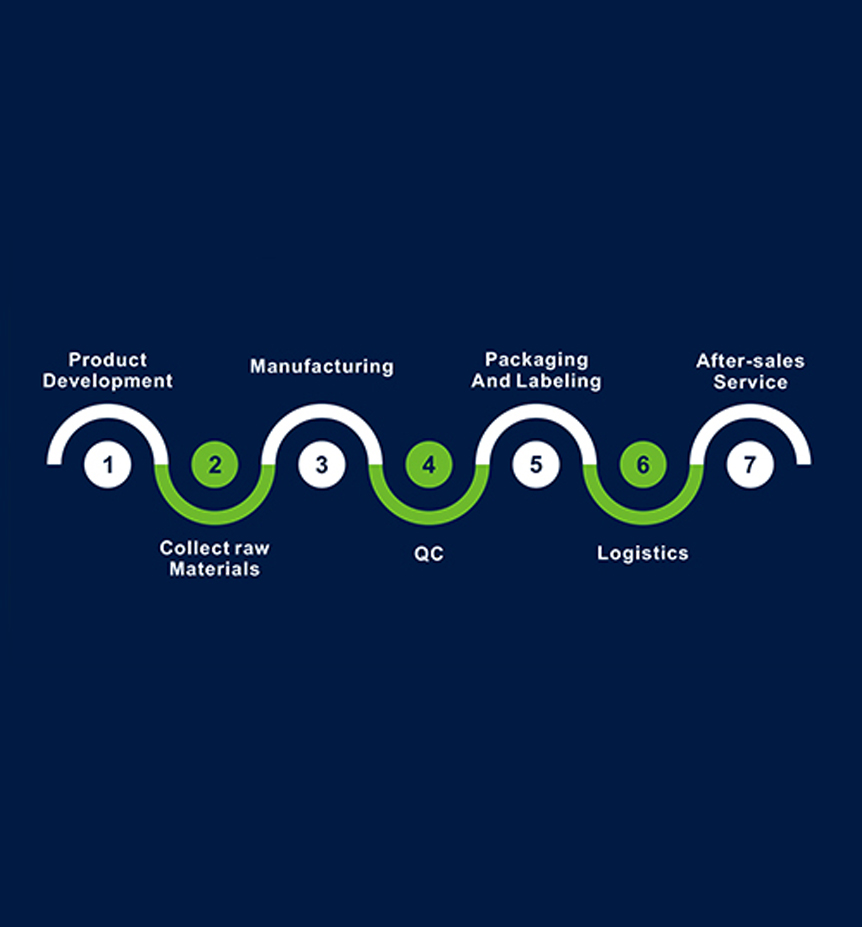

Our quality control process integrates international power connector standards, current technological levels, personnel experience, and feasible test scopes. We focus on detecting quality issues during the production process rather than at the finished product stage. We follow the general standards of raw material quality control, semi – finished product quality control, and finished product quality control. At the product completion stage and in terms of personnel responsibilities, we use a digital system to specify and track the exact values of production process control, and specific team members are assigned to evaluate the control points. In addition, we cooperate with raw material suppliers to conduct relevant tests at their production technology stages rather than in our warehouses.

Services and Advantages

R&D and Manufacturing Capabilities: As a direct Chinese factory, we possess strong R&D capabilities and offer OEM and ODM services. With the necessary machinery and equipment for producing OEM and ODM orders, we can design and manufacture products according to customers’ specific requirements, providing customized solutions.

Product Warranty: We have full confidence in the quality of our products and offer an initial 5 – year product warranty from the date of delivery, ensuring peace of mind for our customers.

Price Competitiveness: Thanks to multiple advantages, our products are priced competitively, providing customers with cost – effective options without compromising on quality.

Global Experience: We take pride in our business collaborations with customers worldwide. Having accumulated extensive experience in global projects, we have in – depth knowledge of the market demands and standards in different regions, enabling us to better serve our global clientele.

Corporate Vision and Mission

Our mission is to push the technological development of relevant business areas to the highest level through innovation and our own technical expertise, thereby meeting market demands. Our vision is to achieve limitless possibilities in product supply by manufacturing a comprehensive and reliable product complex for telecommunication network construction, contributing to the development of the global power, communication, and solar energy sectors.

If you are interested in our products or services, please feel free to contact us at info@jera-fiber.com. We look forward to working with you to create a bright future.

JERA LINE

No. 2 – 1, Wangongchi Road, Yuyao, Ningbo, China

-

MANUFACTURER & RND

-

GUARANTEE RESPONSIBILITY

-

OUR FACTORY LABORATORY

-

WHY COMPETITIVE PRICE

-

HOW WE SAVE LOGISTICS COSTS

-

GLOBAL EXPERIENCE

Test reports &certification

Laboratory Testing Equipments

Quality control process

quality testing

Jera Line was founded in 2012 with a clear vision: to provide innovative and dependable cable infrastructure solutions for the telecommunications and utility sectors. In 2013, we introduced our first product line, the Pole Banding System, which not only marked the beginning of our journey but also solidified our dedication to delivering high – quality products through in – house development.

Since then, Jera Line has been on a continuous growth trajectory, steadily expanding our product portfolio. We have introduced a wide range of fiber optic cable accessories, including suspension and tension clamps, splice closures, fiber termination boxes, and drop cable hardware. These products are meticulously designed to support FTTH/FTTX deployments in various and challenging environmental conditions, ensuring seamless connectivity across different scenarios.

Through consistent investment in research and development, tooling, and rigorous testing, we have evolved from a single – product company into a comprehensive manufacturer. Today, we are capable of providing complete passive infrastructure solutions to customers in over 40 countries around the world, demonstrating our global reach and industry – leading capabilities.

At Jera Line, quality control is at the heart of everything we do. We adhere strictly to the ISO 9001:2015 quality management system when receiving raw materials. Our raw materials, which include plastics, fiber cores, steel, metals, wires, aluminum alloys, and more, are carefully selected, and we place great emphasis on choosing reliable suppliers.

During the production process, our semi – finished products undergo strict inspections. We apply both international and self – developed test standards to ensure the quality of our production operations at every stage.

For finished products, we conduct routine tests. These tests can be customized according to our customers’ specific requirements or carried out based on essential tests that comply with European standards such as IEC – 60794 – 1 – 21 and EN – 50483 in our in – house laboratory. As a company that fully complies with the ISO 9001 quality management system, we take full responsibility for the quality of the products we produce.

Here are some details regarding our quality guarantee:

We offer an initial product guarantee of 5 years from the date of shipment for all items.

In certain special circumstances, an extended guarantee may be provided.

However, the product guarantee does not cover situations such as incorrect item orders, improper installation by the end – user, or incorrect warehousing by the end – user.

When third – party entities, such as transportation companies, are involved in the transaction, the product guarantee terms will be subject to further discussion.

We welcome third – party inspection bodies like SGS and BV to inspect the goods before delivery. Additionally, samples from each batch can be sent to customers prior to shipment for verification.

Jera Line is acutely aware of the significance of product quality to a company’s success. We never use second – hand materials and adhere to strict quality control measures. This unwavering commitment to quality not only gives us confidence in our products but also enables us to meet the high – standards and requirements of customers worldwide.

Equipped with an on – site laboratory, we are able to perform a comprehensive range of essential tests in accordance with European quality inspection standards. These tests include UV and temperature aging tests, corrosion aging tests, ultimate tensile strength tests, mechanical impact tests, low – temperature assembly tests, galvanization thickness tests, material hardness tests, fire resistance tests, and temperature and humidity cycling tests, among others.

Our ultimate goal is to build long – term and stable cooperative relationships with our customers, based on trust, quality, and mutual benefit.

-

Test Reports & Certificates

-

Laboratory Testing Equipment

-

Quality control process

-

FINISHED PRODUCTS ROUTINE CONTROL

-

GUARANTEE RESPONSILBITY

-

ISO 9001:

2015

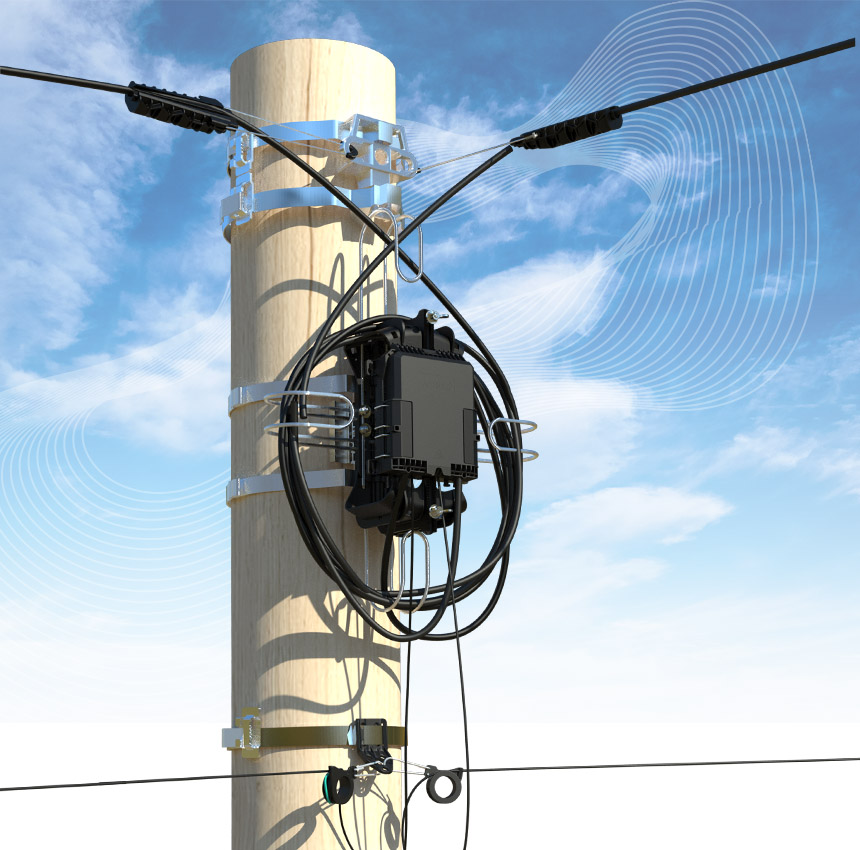

OUTDOOR ODN

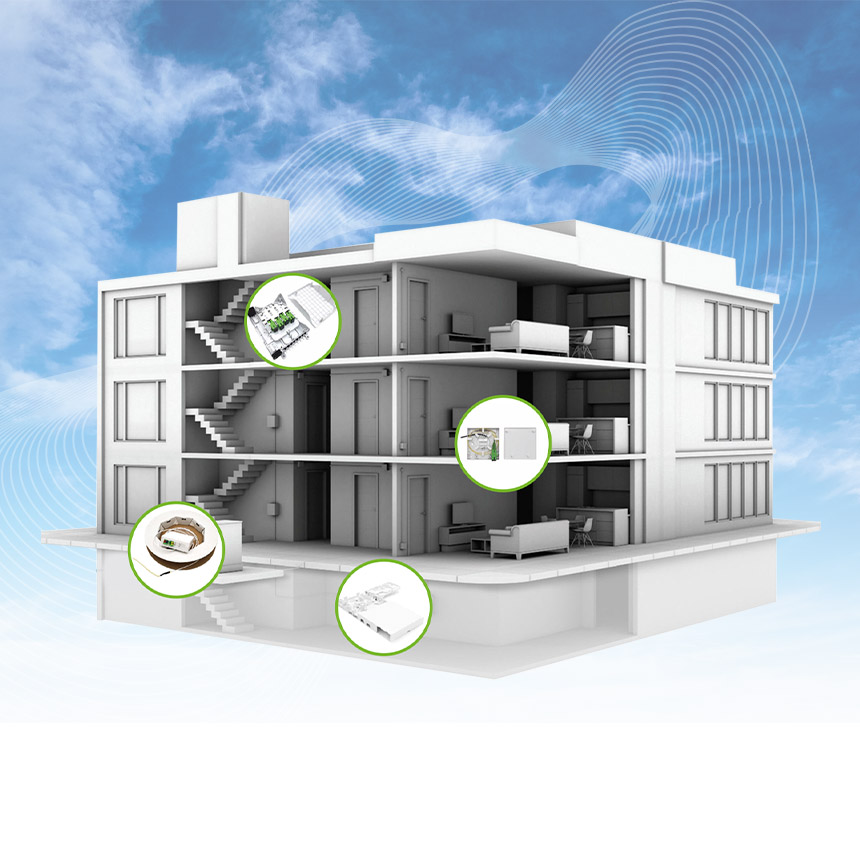

INDOOR ODN

Solutions

At JERA LINE, we pride ourselves on being a leading provider of innovative and reliable solutions in the cable infrastructure domain. With years of industry experience and a commitment to excellence, we have developed a diverse range of solutions tailored to meet the unique needs of various sectors.

1. Telecommunication Network Solutions

In the ever – evolving world of telecommunications, our fiber optic solutions are at the forefront. We offer a complete suite of products for both outdoor and indoor FTTX (Fiber – To – The – X) and FTTH (Fiber – To – The – Home) deployments.

- Outdoor Fiber Optic Solutions:

- Our ADSS (All – Dielectric Self – Supporting) fiber cables are designed to withstand harsh outdoor environments. They are ideal for long – distance transmission in areas where overhead installation is preferred. Paired with our high – quality ADSS cable clamps and tension clamps, these cables ensure stable and efficient signal transmission. For example, in rural areas where laying underground cables is challenging, our ADSS solutions have been successfully deployed to connect remote villages to the main communication network.

- Figure 8 type fiber cables, with their unique design that combines the fiber optic cable and a messenger wire, are another popular choice for outdoor installations. Our range of figure 8 cable clamps and pole bandings provide secure attachment to poles, making the installation process quick and hassle – free.

- Flat and round type fiber drop cables, along with their respective clamps, are used for the last – mile connection to individual premises. These cables are lightweight and easy to install, and our double – jacket type fiber drop cables offer enhanced protection against environmental factors.

- Fiber optic distribution boxes, available in IP – 67 soft rubber type for maximum protection against dust and water, and IP – 54 low – budget type for cost – effective solutions, are crucial for organizing and managing fiber optic connections in outdoor environments. Our pre – connectorized drop cables assemblies and fiber optic outdoor splice closures (IP – 67 heat shrink type) further simplify the installation process and ensure reliable connections.

- Indoor Fiber Optic Solutions:

- In multi – dwelling units (MDUs), our indoor fiber optic solutions are designed to meet the high – density connectivity requirements. Interfloor fiber optic boxes, access terminals, and sockets are carefully crafted to provide easy access for residents. Fiber optic cable drop assemblies and patch cords, along with fiber optic adapters and fast connectors, enable seamless connection of devices within the building.

- Fiber optic PLC (Planar Lightwave Circuit) splitters are used to divide the optical signal among multiple users, making our indoor fiber optic solutions highly scalable. Our fiber network cabling management products, such as optical distribution frames and breakout panels, help in organizing and maintaining the fiber optic network within the building, ensuring efficient operation.

In all our solutions, we adhere to the highest quality standards. We operate in accordance with ISO 9001 and apply international test standards, such as EN – 50483 – 4, NF C 33 020, NF C 33 041, IEC 61238 – 1, and IEC 60099 – 4:2014. Our on – site laboratory, along with partnerships with ISO/IEC 17025:2018 – accredited third – party institutions, ensures that our products are thoroughly tested and meet the requirements of our global customers. Whether it’s a small – scale project or a large – scale infrastructure development, JERA LINE is your trusted partner for all cable infrastructure solutions.

-

Outdoor Fiber Optic Solutions

-

Indoor Fiber Optic Solutions

blogs

- Our Story

- Sales & Deals

What is Hypoclamp Aerial Cable Clamps?

-

Jun-28 2025

What is Hypoclamp Aerial Cable Clamps?

Hypoclamp Aerial Cable Clamp, also known ... -

Jun-26 2025

What is Fibre Optic Drop Mandrel Clamp?

Fibre Optic Drop Mandrel Clamp is the sam... -

Jun-24 2025

What is FTTH-001 Optical box Optical socket?

The FTTH-001 optical box, which incorpora...

What is Hypoclamp Aerial Cable Clamps?

-

Jun-28 2025

What is Hypoclamp Aerial Cable Clamps?

Hypoclamp Aerial Cable Clamp, also known ... -

Jun-26 2025

What is Fibre Optic Drop Mandrel Clamp?

Fibre Optic Drop Mandrel Clamp is the sam... -

Jun-24 2025

What is FTTH-001 Optical box Optical socket?

The FTTH-001 optical box, which incorpora...